To discover more about drone propellers, DJI Focus magazine sat down with an engineer from DJI’s R&D Team. The following is an excerpt from that exclusive interview.

![]()

Q: How do you go about designing a drone propeller?

A: Every aspect of a new drone dictates what is needed of the propeller. After analyzing the propulsion system, flight time, max speed, and prop mounting method, we can start designing the propeller and motor.

Q: How are the propellers in each DJI consumer drone different?

A: Since propellers are both removable and essential to aircraft performance and safety, we must start with how they mount to the overall structure.

For the Phantom 1, 2, and 3, we opted for self-tightening propellers, threaded in a way that prevents them from detaching during flight. With the Phantom 4, we introduced quick-release propellers, which cannot rotate unless pressed down manually. With increased safety and convenience, we’ve stuck with this design ever since.

Another way to distinguish propellers, aside from the drone on which they are mounted, is the combination of letters and numbers embossed on them. Are these random? Actually, these are identifying marks. For example, a Mavic Pro propeller includes the code 8330F, which is packed with meaning:

• 83 refers to an unfolded propeller diameter of 8.3 inches

• 30 refers to a propeller pitch of 3.0 inches. *

• F refers to this propeller being foldable

Not random after all!

* The distance a propeller would travel in one revolution if it were moving through a soft solid.

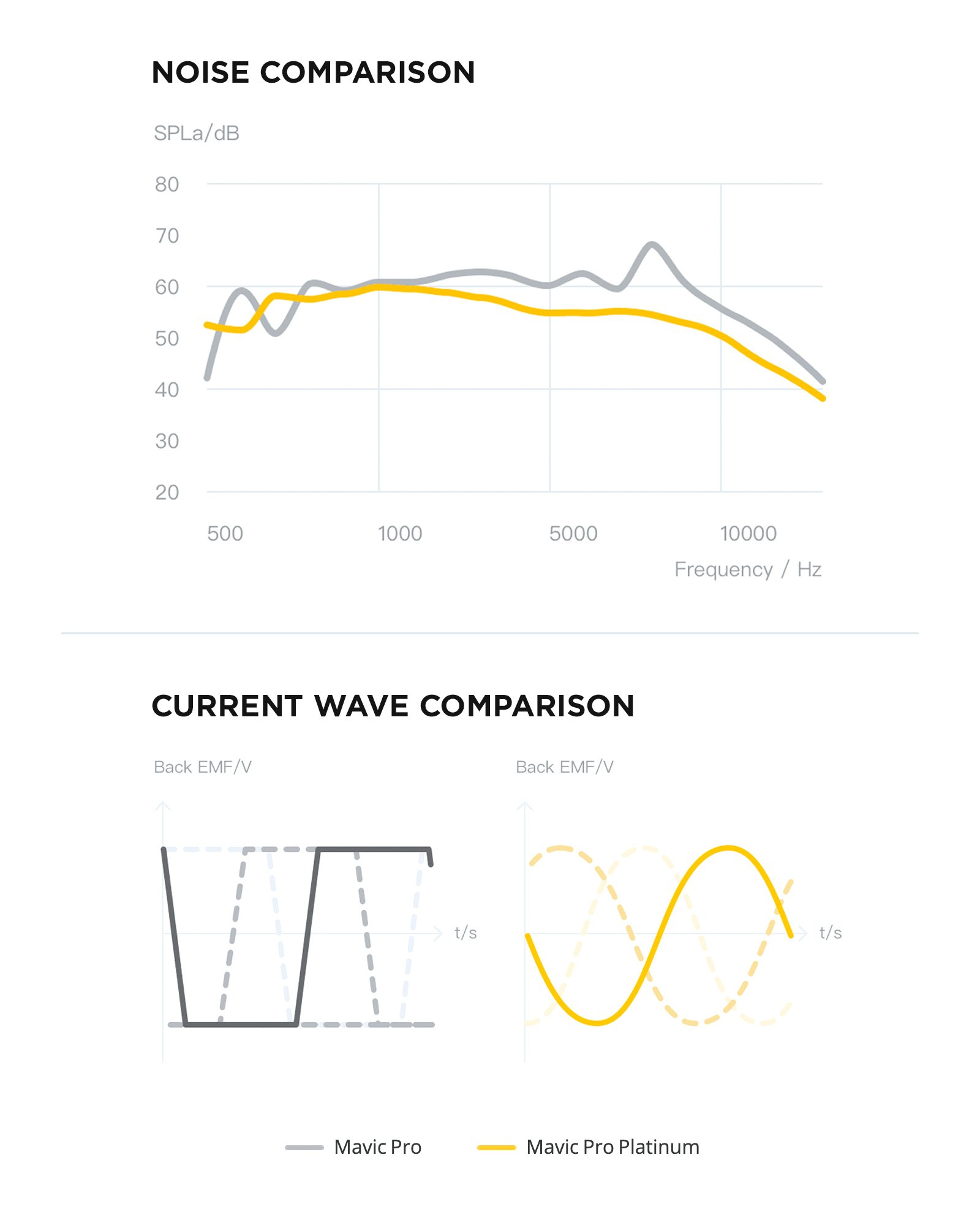

Q: How do you reduce the noise of propellers?

A: As a propeller rotates, it slices through the air at a high speed, producing a sharp buzzing sound. We can reduce this noise in two ways.

The first is to change the propeller shape. An optimized shape reduces motor speed during flight, lessening the impact with the air and reducing noise.

The second way lies in the design of the propeller’s tip. As the blade spins, the speed at the tip is the fastest. Based on this principle, designing the propeller tip to be slightly swept back into a narrower shape reduces air slicing and makes the propeller quieter.

Q: If the propeller is installed incorrectly, can the drone take off?

A: Four-axis multi-rotor UAVs are now all equipped with four propellers – two clockwise and two counter-clockwise, which provides balanced propulsion.

With this in mind, DJI has taken into account the possibility of mounting propellers incorrectly. This can be avoided because if a propeller is matched with the wrong motor, it cannot be mounted at all. If a propeller is forced on the wrong motor, it will not provide lift, the app will report an error, and the drone will be unable to take off.

We hope these insights from our dedicated R&D help shed light on this integral part of drones. Without reliable, well-designed propellers, our aircrafts could not be what they are today. By incorporating intuitive and convenient use, your flight experience is enhanced with what we believe are the best-designed propellers out there.